Nowadays, Coronavirus becomes one of the most viruses that are risky to human beings; most of the hospitals can’t help all the infected people by this virus. By the same token, all hospitals in the world are facing a shortage of respiratory equipment due to this virus, especially mechanical ventilators. Because of the lack in the ventilators, there are many people die; these machines can save people life -after Allah-.furthermore, the main objective of our project is to design mechanical ventilators which it is easy to implement and portable to assist the Coronavirus’s patients. These two features would have a financial impact; because not all people will afford the standard and reliable Ventilator, and medical impact because it can assist the hospitals in dealing with the shortage.

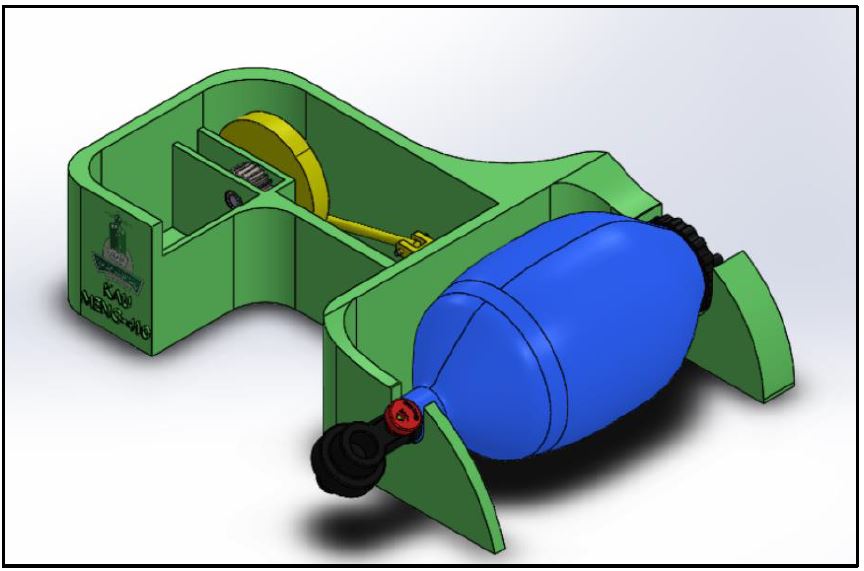

We provide three alternatives to our project, each of them has a different feature; the first alternative is the Arm ventilator; it is made of two aluminum profiles, an acrylic base, two arms, and a gear system. Its gear system connected to the arms to transmit the required force to the Ambu-bag, and by this process, the Ventilator can help the patient to breathe. The second alternative is the Power screw ventilator which consists of a stepper motor, two guide rods, a power screw and arm. The Ambu-bag will compress and expand due to the force that is coming from the arm, this arm will get the required power after the stepper motor rotates the power screw. Through this process, the Ventilator can assist the patient to breathe. The third alternative is the 3D printed Ventilator, which consists of two shafts, two bearings, one set of spur gear, a disc, and an arm. All the components are printed by 3D-Printer using PLA filament. The system works by the spur gear that transfers the power from the motor to the shaft that has the disc; The disc will generate reciprocating motion to transfer the force to the arm, then the arm will compress and expand the Ambu-bag to help the patient to breathe.

All in all, depending on the Kepner Tregoe decision analysis (KTDA), we obtained a higher score to choose it as the appropriate solution to minimize the shortage of ventilators. The third alternative got a higher score, which is the 3D printed Ventilator comparing to the other alternatives, so we chose it as the recommended solution.

In the implementation approach, we will go through the four primary phases. The first one is the project initiation, which clarifies the client requirements. The second one is the project planning, which is defining all the phases and activities by using MS office programs and Gantt chart. The third one is the project execution, which is complete all the phases and activities to achieve the build-up phase; it is done by using MITCalc and finite element analysis. The last one is the project closure, which is a list of steps that is important to release the deliverables to the business.